CNC Automatic Steel 2D Wire Bending Machine

The cnc automatic steel 3d wire bending machine is a high-tech tool. It bends steel wire accurately into 3D shapes. Ideal for various industries. Ensures quality and efficiency.

Product Description

Introduction of CNC Automatic Steel 2D Wire Bending Machine

The CNC automatic steel 3D wire bending machine is a state-of-the-art device. It combines computer numerical control technology with advanced bending capabilities. Capable of precisely shaping steel wire into complex 3D forms. Offers high efficiency, accuracy, and repeatability. Reduces production time and labor costs. Enhances design flexibility and product quality. A valuable asset for any modern manufacturing operation.

Product Specification of CNC Automatic Steel 2D Wire Bending Machine

| Name | CNC Automatic Steel 2D Wire Bending Machine |

| Machine model | ZX3D 6-12 |

| Wire diameter | 6-12mm iron wire |

| Feeding wire wheels sets | 4 groups |

| Feeding wire length | 40 m/min |

| length * width * height | 3900*1450*1650MM |

| Interface Lanquage | Chinese/English |

| CNC axis quantity | 5-axis (apan Sanyo brand motor) |

Feature and Application of CNC Automatic Steel 2D Wire Bending Machine

The CNC automatic steel 3D wire bending machine has multiple functions. It can bend steel wire into intricate 3D shapes with high precision. It offers programmable settings for custom designs. This machine is widely applied in various fields. In the automotive industry, it is used for making wire components. In electronics, it helps in manufacturing connectors.

Instructions:

Instructions for CNC bending machine: Load material. Set parameters via computer control. Start the machine. Monitor the process. After use, clean and maintain. Ensures accurate bending. Ideal for industrial applications.

How To Use:

Instructions for CNC Automatic Steel 3D Wire Bending Machine: Preparation: Inspect the machine for any damage. Ensure proper power supply and connection.

Loading Steel Wire: Place the steel wire carefully into the loading mechanism. Secure it properly.

Setting Parameters: Use the computer control panel to input desired 3D shapes, bending angles, and other parameters.

Operation: Start the machine. Monitor the bending process through the display. Make adjustments if needed.

Completion: Once the bending is complete, turn off the machine and remove the bent wire.

Maintenance: Regularly clean and lubricate the machine. Check for wear and replace parts as necessary. This machine offers high precision and efficiency in bending steel wire into 3D shapes.

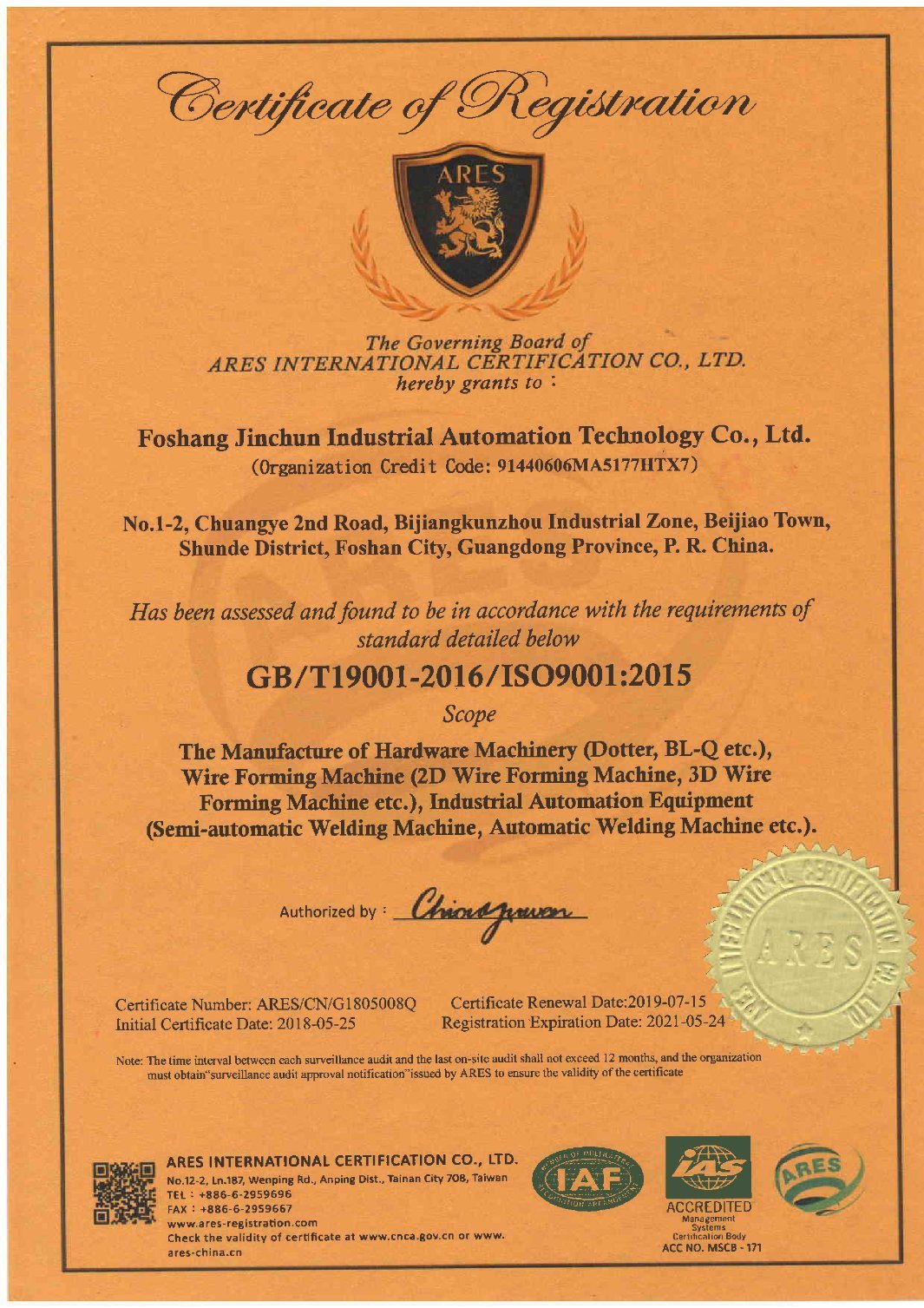

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q:How to operate the machine?

A: Our technicians have installed the machine before shipment. For the installation of some small parts, we will send detailed training videos and user manuals together with the machine. 95% of customers can learn by themselves

Q:The voltage standard of our country is not consistent with that of your country. Can you design according to the parameters provided by us?

A:Of course, we can design the machine according to the voltage standard of your country

Q:Does the machine can be customized according to my requirements?

A: Sure, we have a strong technical team and have rich experience. Our goal is to make you satisfied.

Q:Can you arrange the shipment for me?

A: We can arrange the shipment for our clients by sea or by air. Trading terms FOB, CIF, EXW are available.

Q:Can you make the logo or company name on the products or package?

A:Sure. customer's logo or company name can be printed on products by stamping, printing, embossing, coating or sticker.

Q:Can we use English or other languages on the display screen?

A:Yes, can. The system can achieve many languages, such as English, French, Russian, Spanish, and other languages

If you want more product information, please feel free to contact us!