Small 2D Wire Bending Machine

The Small 2D wire bending machine offers compact design for precise wire bending. Ideal for small-scale production and hobbyist use.

Product Description

2D Wire Bending Machine

Introduction of Small 2D Wire Bending Machine

The Small 2D wire bending machine is a versatile and compact tool. It is designed to bend wires precisely in two dimensions. Ideal for small-scale production, workshops with limited space. Offers ease of use and reliable performance for creating various wire shapes.

Product Specification of Small 2D Wire Bending Machine

| Name | Small 2D wire bending machine |

| Electrical voltage | 3Phases 4 wires+ground wire |

| diameter | 2.5--6 |

| Welding module | 2 sets of robot clamps |

| 40KW welding transformer | |

| 90 medium frequency transformer | |

| 300A argon arc welding machine *2/3 |

Feature and Application of Small 2D Wire Bending Machine

The Small 2D wire bending machine offers several functions. It can accurately bend wires into different two-dimensional shapes and angles. With adjustable settings, it accommodates various wire sizes.

Application areas: chicken coops, barbecue grills, steamer racks, flower racks.

Instructions:

Instructions for Small 2D Wire Bending Machine: Load wire. Set bending parameters on the machine. Start operation. Monitor the process. After use, clean and maintain regularly. Ideal for small-scale wire bending tasks, suitable for hobbyists and small workshops. Ensure safety during operation.

How To Use:

For the Small 2D wire bending machine, here are some important points to note:

Operation Precautions:

1.Before using the machine, carefully read the user manual to understand its functions and operation methods.

2.Check the machine for any damage or loose parts before starting. Ensure all connections are secure.

3.Use only wires of appropriate size and material as specified by the manufacturer. Using incorrect wires may damage the machine or result in inaccurate bending.

4.Set the bending parameters accurately. Incorrect settings can lead to faulty products or damage to the machine.

5.Keep your hands and other body parts away from the moving parts of the machine during operation to prevent injury.

6.Wear appropriate safety gear such as gloves and safety glasses if necessary, especially when handling sharp wires.

Maintenance Precautions:

1.After use, clean the machine regularly to remove dust, wire debris, and other contaminants. This helps maintain its performance and prolong its lifespan.

2.Inspect the machine periodically for wear and tear. Replace any damaged parts promptly to ensure safe and accurate operation.

3.Store the machine in a dry and clean place when not in use to prevent corrosion and damage.

4. Follow the manufacturer's recommended maintenance schedule and use only genuine spare parts for repairs.

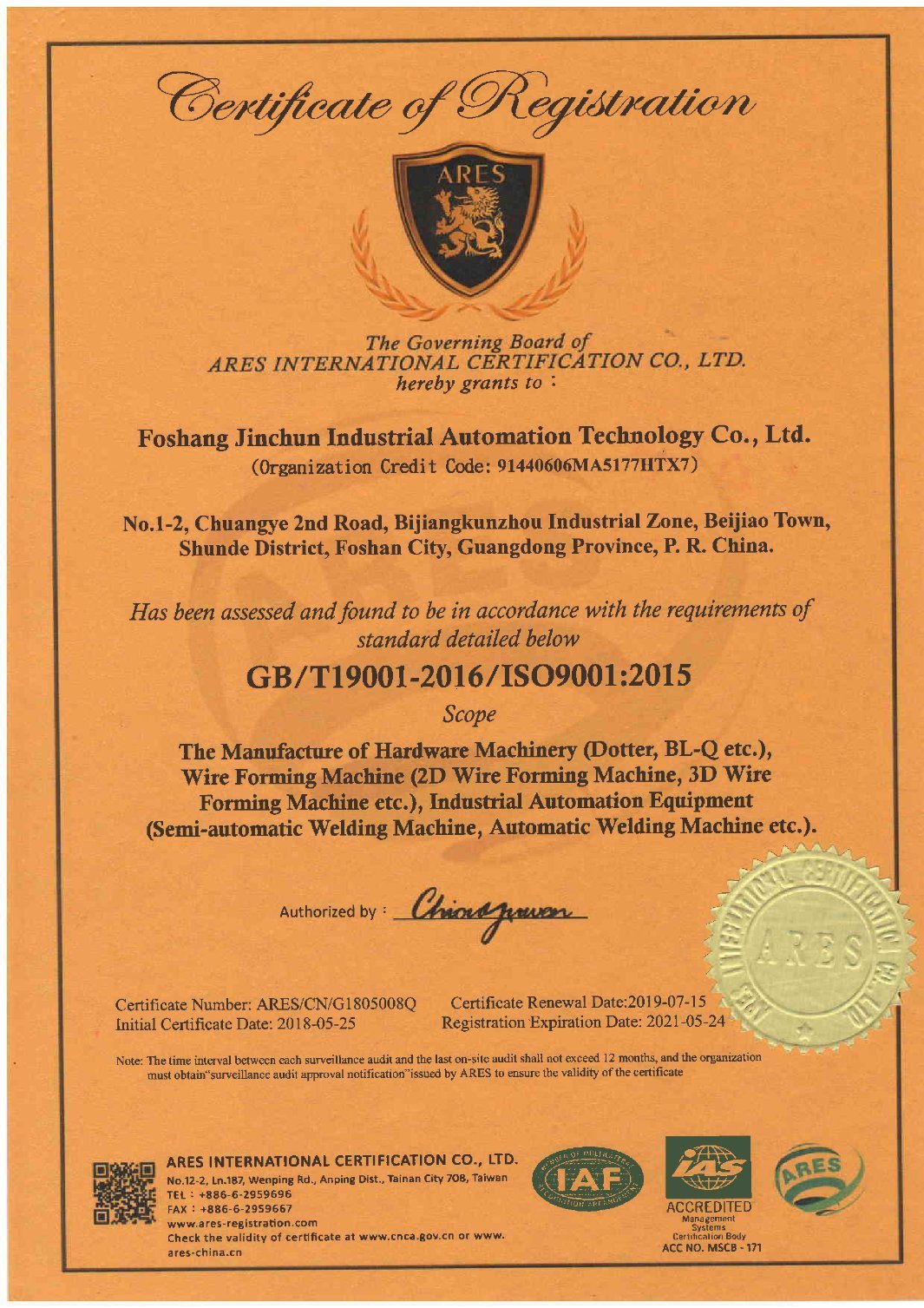

Product Qualification

|

|

Deliver, Shipping and Serving

Professional ODM&OEM Lash Glue Remover Products Manufacturer for over 20 years. We appreciate cooperation with you.

|

|

FAQ

Q1. Why choose us?

A. Our founding team has more than 20 years of experience in the R&D and manufacturing industry of metal forming and welding machinery. What we offer is a good product at a reasonably price.

Q2. Can I customize the product?

A. Yes . We can customize production equipment solutions according to your product requirements.

Q3. Can I get a sample?

A. Yes. But the proofing cost and shipping are negotiated by both parties.

Q4. What's the delivery time?

A. The delivery time needs to be determined by both parties through negotiation .

Q5. How do I order from you?

A. Consulting → equipment plan quotation →negotiation→ prototyping →PO/PI→ payment deposit → production → debugging →delivery→further.